Solutions

We provide a quick fix to the problem that you face.

Excellence in Industrial Automation: A Showcase of Precision and Innovation

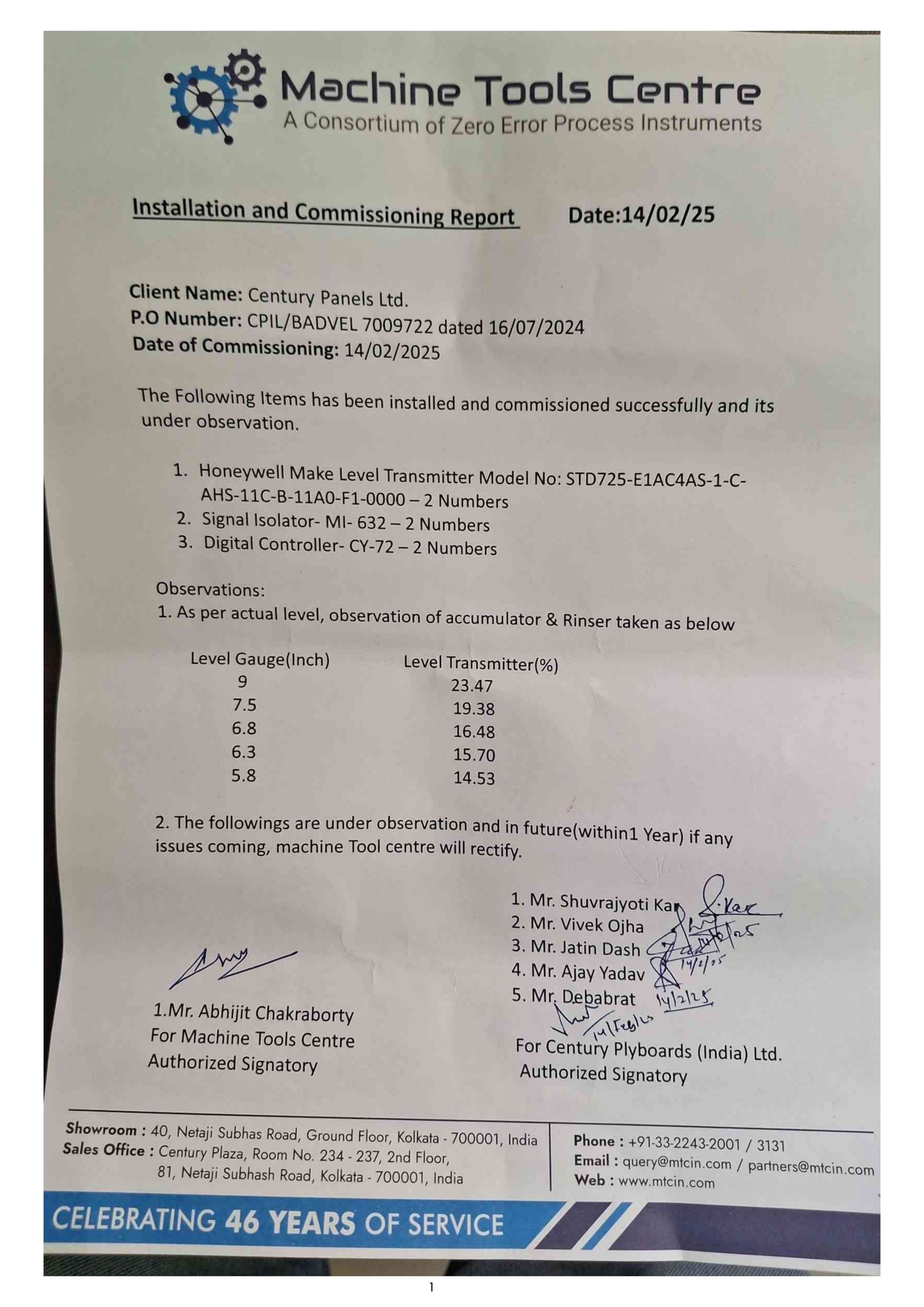

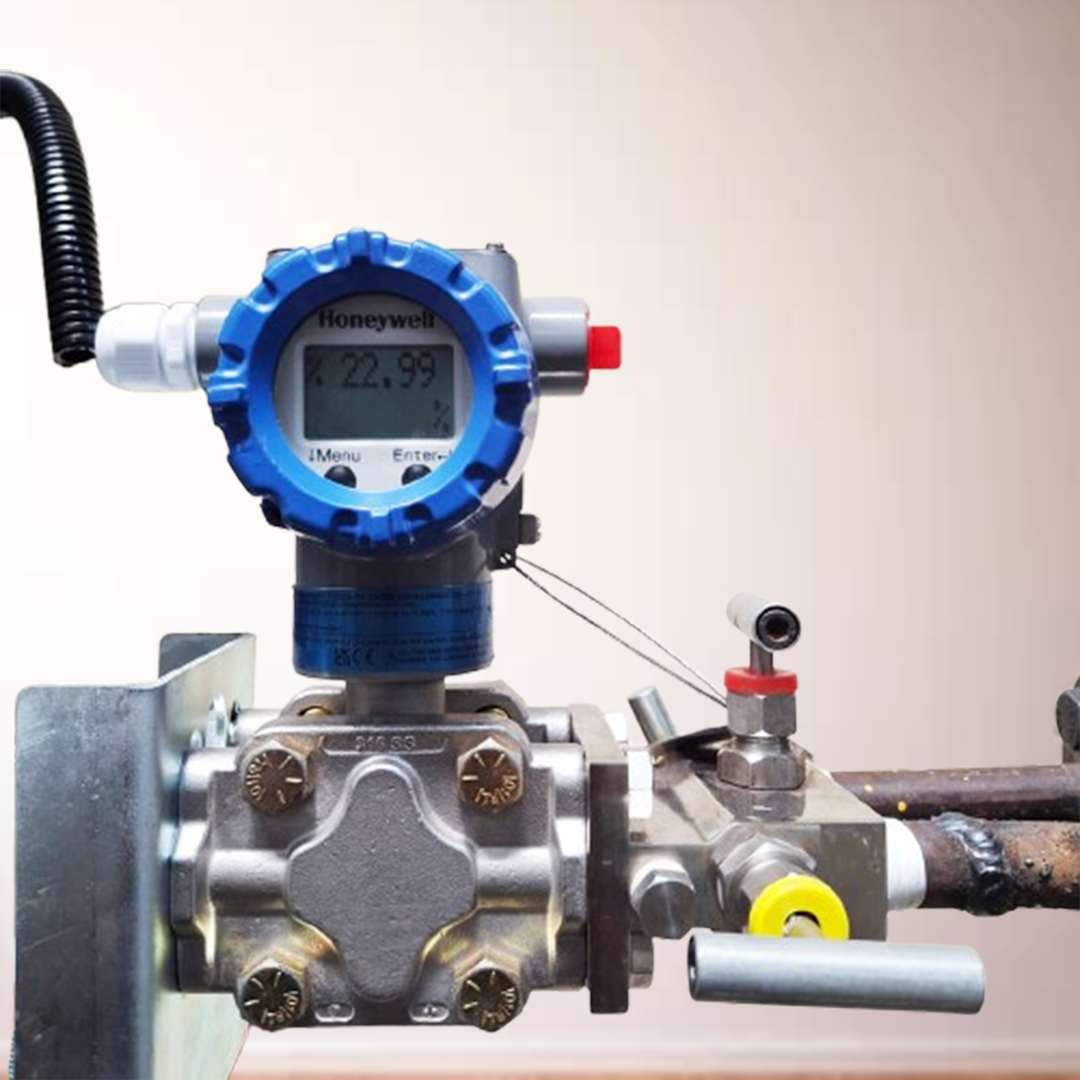

At Machine Tools Centre (MTC), we pride ourselves on delivering innovative and reliable industrial automation solutions that drive operational success. In a recent project, we expertly upgraded a level gauge system, incorporating state-of-the-art technology for enhanced precision. Our team efficiently modified pipelines, installed a Honeywell Transmitter with a 3-way manifold, and ensured seamless data flow through custom circuits. We conducted rigorous leak testing, precise calibration, and fine-tuned valve adjustments to guarantee flawless operation. With the integration of a cutting-edge digital display and continuous 24-hour monitoring, the system was optimized for maximum efficiency and reliability. This achievement reflects MTC’s unwavering commitment to excellence and our ability to deliver top-tier automation solutions.

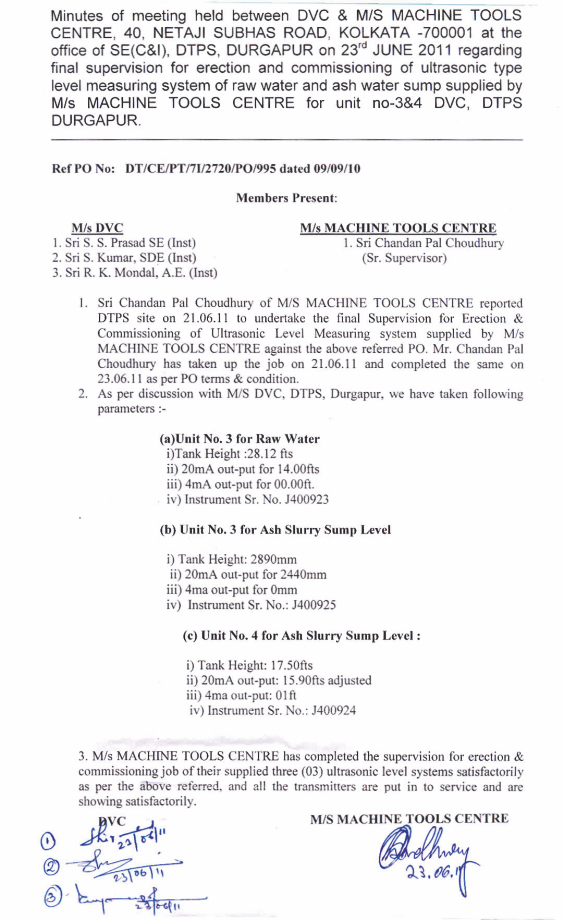

Smooth Installation Of Electromagnetic Flowmeter at Sidhabari!

Machine Tools Centre recently completed the installation of an 600 mm line Size Electromagnetic Flowmeter at CLW Sidhabari. Our expert installation team’s dedication and precision ensure top-notch performance and reliability in every project.

You can trust Machine Tools Centre to deliver advanced process automation solutions for all your industrial needs!

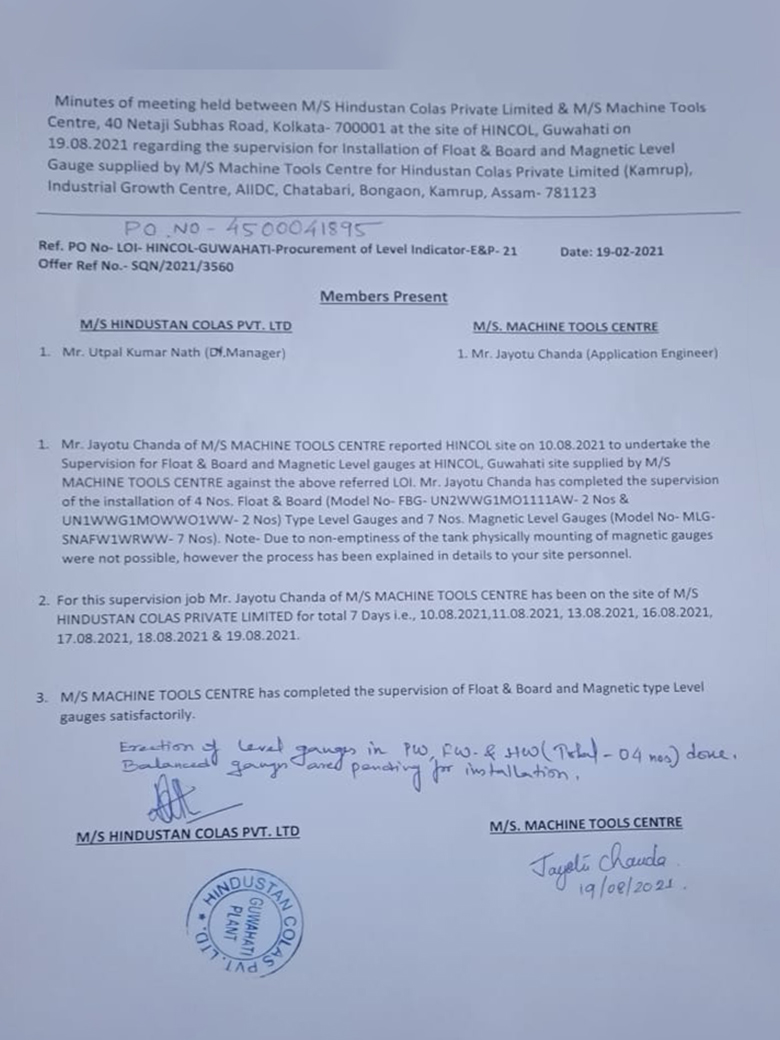

Hincol Float and Board type Level Gauge Installation project in Guwahati

We recently completed the “Hincol Float and Board type Level Gauge Installation” project in Guwahati. Not only did we supply the high-quality “Level Gauge” for this project, but our dedicated team also handled the installation process from start to finish.

Check out the images from the Hincol project:

For us, it’s not just about supplying products, it’s about empowering businesses with reliable solutions.

Contact us today to learn how we can support your next installation project with our expertise and dedication.

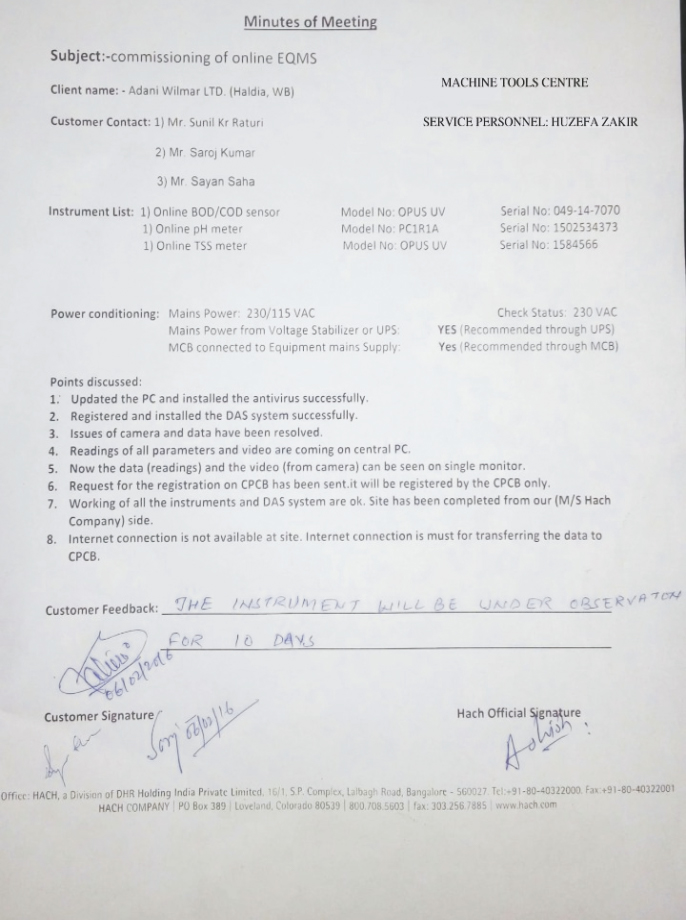

EFFLUENT QUALITY MONITORING SYSTEM

Online Analyzer with Data Aquisition System are installed for measurement of “BOD”, “COD”, “pH”, “TSS” from the waste discharge from Effuluent Treatment plant. ETP (Effluent Treatment Plant) is a process design for treating the industrial waste water for its reuse or safe disposal to the environment. Online monitoring systems provide continuous measurement of data for long periods of time, at the monitoring site of interest. Goals:

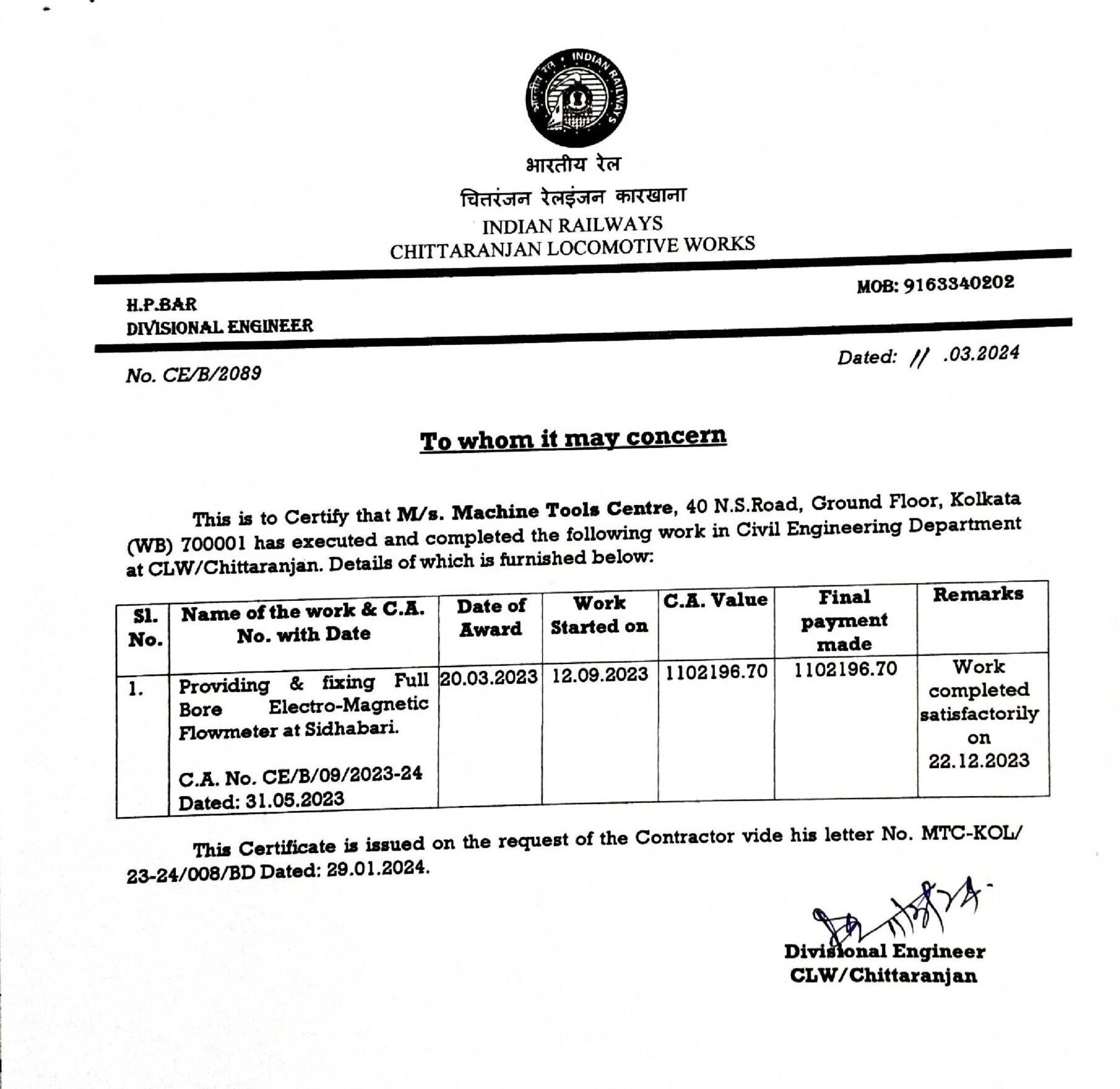

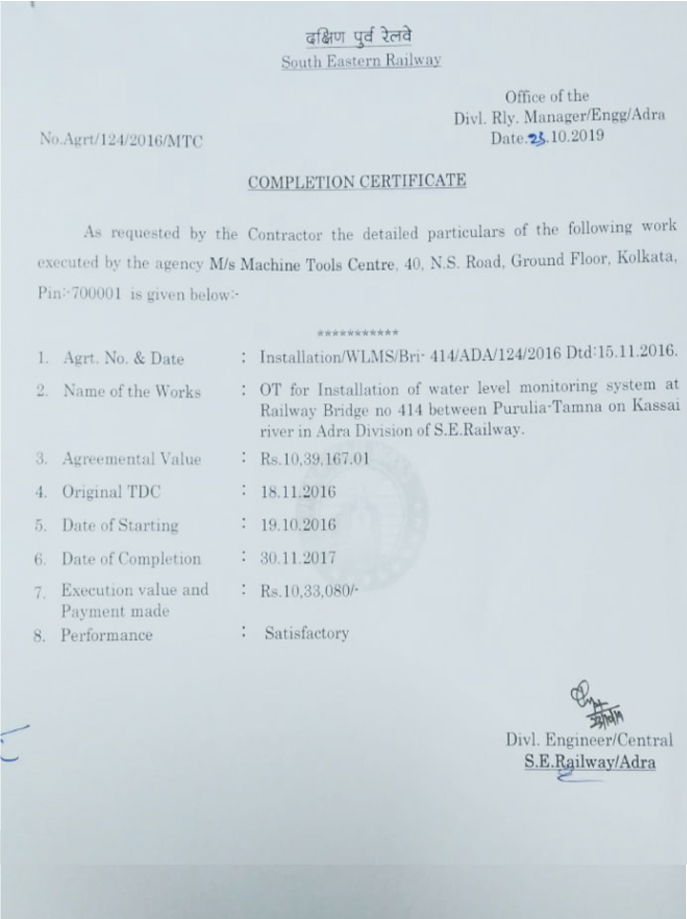

WATER LEVEL MONITORING SYSTEM

One of the major problems faced by most the countries is the issue of water scarcity in the world and wastage during transmission has been identified as a major culprit; this is one of the motivations for this research, to deploy computing techniques in creating a barrier to wastage in order to not only provide more financial gains and help the environment as well as the water cycle which in turn ensures that we save water for our future. IOT-based Water Level Monitoring system is an innovative system that will inform the users about the level of liquid and will prevent it from overflowing. To demonstrate this the system makes use of containers, where the Ultrasonic/Radar sensors are placed over the containers to detect the liquid level and compare it with the container’s depth. The system makes use of an AVR family microcontroller, Raspberry Pi, LCD screen, Wi-Fi modem for sending data, and a buzzer. A 12 V transformer is used for the power supply in this system. The LCD screen is used to display the status of the level of liquid in the containers. The liquid level is highlighted as colored to show the level of liquid present in the container with the help of a web page to the user. The buzzer starts ringing when the set limit of the liquid is crossed. Thus this system helps to prevent the wastage of water by informing about the liquid levels of the containers

OPEN CHANNEL FLOW MEASUREMENT SYSTEM

The common method of measuring flow through an open channel is to measure the height or HEAD of the liquid as it passes over an obstruction (a flume or weir) in the channel. Using ultrasonic level technology, Open channel flow meters include a non-contacting sensor mounted above the flume or weir. Open Channel Flowmeter performs flow measurement of liquids that are open to the atmosphere at some point in the flow measurement path. The liquid may be entirely open to the atmosphere and may be contained in a closed pipe. Regardless of which type of open channel flow measurement techniques are used, level measurement must be used in combination with velocity measurement and a flow computer using the manning equation of open channel flow to calculate the true flow rate of any wetted channel.