WIKA PRODUCTS

- WIKA Products

- Applications & Industries

- Installation

- FAQs

Top WIKA Products

WIKA offers a wide range of high-quality instruments for accurate monitoring. Whether you need a WIKA pressure gauge, a pressure transmitter, or a flow switch, WIKA products meet the highest standards.

1. WIKA Pressure Gauges

WIKA pressure gauges are known for their durability and precision. They are used in many industries like manufacturing, oil & gas, and HVAC. Available in:

- Bourdon Tube Pressure Gauges – Ideal for general industrial applications.

- Diaphragm Pressure Gauges – Best for corrosive or viscous media.

- Differential Pressure Gauges – Perfect for monitoring pressure differences in filtration and flow systems.

- Digital Pressure Gauges – Advanced electronic measurement with high accuracy.

2. WIKA Pressure Transmitters

WIKA pressure transmitters convert pressure readings into electronic signals. They are perfect for automated systems and real-time monitoring. Used in hydraulic, pneumatic, and process industries.

Popular models include:

- Standard Pressure Transmitters – General-purpose, highly reliable sensors.

- Industrial Pressure Transmitters – Robust designs for harsh environments.

- Sanitary Pressure Transmitters – Specially designed for food, beverage, and pharmaceutical industries.

- Submersible Pressure Transmitters – Ideal for liquid-level monitoring applications.

3. WIKA Pressure Sensors

WIKA pressure sensors provide digital accuracy and quick response times. They are used in automated production lines, automotive testing, and fluid processing.

Types of WIKA pressure sensors include:

- Absolute Pressure Sensors – These measure pressure relative to a vacuum.

- Gauge Pressure Sensors – Compare pressure against atmospheric pressure.

- Differential Pressure Sensors – Used in filtration, pump monitoring, and HVAC.

4. WIKA Flow Switches

WIKA flow switches ensure optimal flow regulation in piping systems and industrial processes. They detect flow changes and trigger alerts or shut-off mechanisms when needed.

Available types include:

- Mechanical Flow Switches – Operate using paddle or piston mechanisms.

- Electronic Flow Switches – Provide real-time flow monitoring with digital output.

- Thermal Flow Switches – Used in temperature-sensitive applications.

5. WIKA Pressure Switches

WIKA pressure switches automate and safeguard industrial systems. They activate electrical contacts based on pressure levels. Used in compressors, pumps, hydraulic systems, and safety controls.

Variants include:

- Mechanical Pressure Switches – Reliable and easy to integrate into industrial setups.

- Electronic Pressure Switches – These offer digital precision and programmable settings.

Applications & Industries

WIKA instruments are used in many industries for measuring and controlling pressure:

- Oil & Gas – Use WIKA pressure sensors to keep pipelines safe.

- Manufacturing & Automation – Get precise control with WIKA gauges and transmitters.

- HVAC & Refrigeration – Keep temperature and pressure balanced with WIKA flow switches.

- Pharmaceutical & Chemical Processing – Monitor with precision using WIKA pressure gauges.

- Energy & Power Generation – Boost system efficiency with WIKA pressure transmitters.

WIKA products are top-notch in accuracy and reliability, no matter your industry.

Installation & Maintenance

Setting up and keeping WIKA instruments running is easy:

- Easy Installation – Follow clear instructions for setting up WIKA gauges, transmitters, and sensors.

- System Compatibility – They fit seamlessly into industrial systems.

- Durability – Built to handle tough environments.

- Minimal Maintenance – Regular calibration keeps them accurate for a long time.

Our expert team is here to help with installing WIKA products for the best results.

Customer Support & FAQs

What Types of Measurements Do WIKA Instruments Provide?

WIKA instruments measure pressure, temperature, and flow. They offer accurate monitoring solutions.

How Do I Choose the Right WIKA Product?

Our experts can help you pick the perfect WIKA pressure gauge, transmitter, or switch for your needs.

Are WIKA Products Easy to Install?

Yes, WIKA instruments are designed for easy installation. They come with simple instructions.

What Kind of Support Does WIKA Provide After Purchase?

We offer technical help, troubleshooting, and training. We ensure that you get the most from WIKA products.

Are WIKA Products Covered Under Warranty?

Yes! WIKA instruments have a comprehensive warranty for your peace of mind.

Can WIKA Instruments Be Used in Automated Systems?

Absolutely! Many WIKA pressure sensors and transmitters work well in industrial automation.

Showing 1–12 of 50 results

-

Bourdon tube pressure gauge, copper alloy Models (WIKA)

-

Bourdon tube pressure gauge with switch contacts type PGS23

-

Bourdon tube pressure gauge, copper alloy, Stainless steel case, liquid filling 213.53.100 (WIKA)

-

SS Case Brass Pressure Gauge Bourdon type Model AT (BAUMER)

-

Diaphragm pressure gauge Model 432.50 (WIKA)

-

Diaphragm pressure gauge for the process industry, Model 432.56, 432.36

-

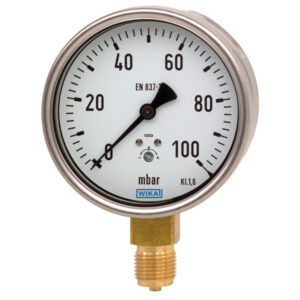

Capsule pressure gauge, stainless steel Model 632.50 (WIKA)

-

Capsule pressure gauge, copper alloy Stainless steel case Model 612.20 (WIKA)

-

Test gauge, safety version Model 332.30 (WIKA)

-

Test Gauge, Copper Alloy, Model 312.20 (WIKA)

-

Bourdon Tube Pressure Gauges Stainless Steel, Solid Front Case type 232.30 (WIKA)

-

Differential Pressure Gauge type 732.14 & 762.14