MASS

- Precision Measurement

- Key Specifications

- Installation Process

- FAQs

MASS pressure gauges are recognised for their reliability and precision in various settings.

- High Precision: Engineered for accurate pressure measurements, ensuring optimal performance in critical applications.

- Robust Design: Constructed from durable materials that can withstand harsh operating environments.

- Versatile Formats: Available in analog and digital styles, catering to diverse user preferences.

- Wide Application Range: Suitable for industries such as manufacturing, HVAC, and automotive.

- Customisable Options: Features tailored to meet specific measurement requirements for enhanced functionality.

Reliable Performance: Known for consistent accuracy and adherence to industry standards for safety and quality.

Key Specifications of MASS Pressure Gauges

| Specification | Details |

|---|---|

| Pressure Range | Typically from vacuum to 1000 bar (14,500 psi) |

| Accuracy | ±0.25% to ±1% of full scale, depending on model |

| Display Type | Analog dial or digital display options available |

| Connection Size | Common sizes include 1/4″, 1/2″, or 3/8″ NPT |

| Dial Size | Available in various sizes (e.g., 63mm, 100mm, 150mm) |

| Operating Temperature | -40°C to 60°C (-40°F to 140°F), depending on the model |

| Case Material | Stainless steel or plastic options for durability |

| Media Compatibility | Suitable for gases and liquids, specific to model |

| Ingress Protection | IP54, IP65, or higher ratings available |

| Calibration | Factory calibration certificates provided |

These specifications highlight the reliability and versatility of MASS pressure gauges in various industrial applications.

Installation Process for MASS Pressure Gauges

Installing MASS pressure gauges correctly is crucial for ensuring accurate measurements and optimal performance. Following a systematic installation process helps avoid errors and potential leaks. Here’s a step-by-step guide for proper installation:

- Location Selection: Choose a stable and accessible spot on the pipeline or vessel, ensuring minimal pressure fluctuations.

- Surface Preparation: Clean the mounting surface thoroughly. If necessary, use a mounting bracket for added stability.

- Connection Compatibility: Confirm that the gauge’s connection size matches the pipe fitting. Use adapters if required.

- Secure Installation: Apply thread sealant tape, connect the gauge, and tighten it securely without overtightening.

- Leak Testing: Activate the system and check for leaks. Calibrate the gauge according to the manufacturer’s instructions before putting it into full operation.

Following these steps ensures a reliable installation and accurate pressure readings.

FAQs

What Types of Pressure Gauges Are Available?

MASS offers various types, including analog (Bourdon tube), digital, and diaphragm gauges, each suited for different applications.

How Do I Choose the Right Pressure Gauge for My Application?

Consider factors such as pressure range, media type, accuracy requirements, and environmental conditions, including corrosion resistance.

What is the Typical Accuracy of a Mass Pressure Gauge?

Accuracy generally falls within ±1% to ±2% of full scale for industrial gauges; refer to specific product specifications for details.

How Should I Install a Pressure Gauge?

Ensure a proper connection, use thread sealant to prevent leaks, and position the gauge for easy readability and access. Calibration may be required before use.

What Maintenance is Needed for Pressure Gauges?

Regularly inspect for leaks, check diaphragm condition (for diaphragm gauges), and calibrate as needed to ensure accurate readings. Cleaning is also recommended to prevent buildup.

What Should I Do if My Pressure Gauge is Giving Inconsistent Readings?

Check for leaks or physical damage first. If the gauge seems intact, recalibration or replacement may be necessary. Consult manufacturer guidelines or a professional technician for assistance.

Showing 1–12 of 36 results

-

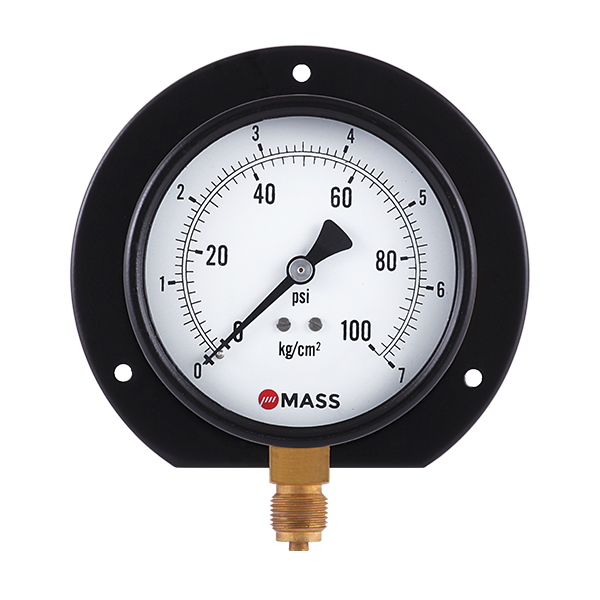

PG 120 Utility Pressure Gauge (MASS)

-

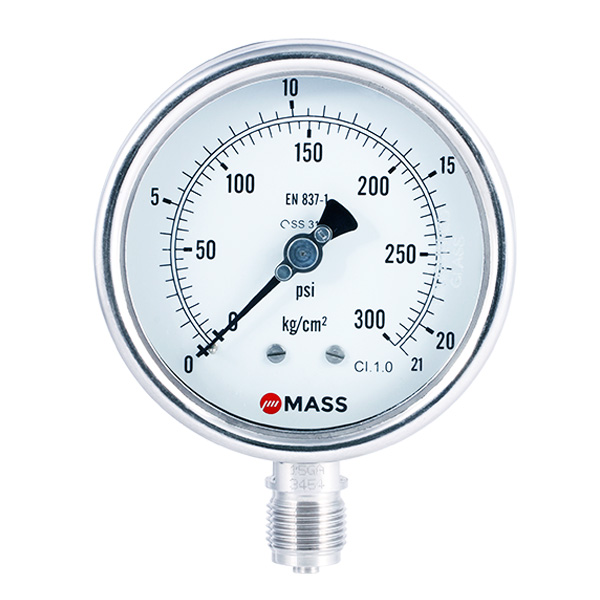

PG 121 Utility Pressure Gauge (MASS)

-

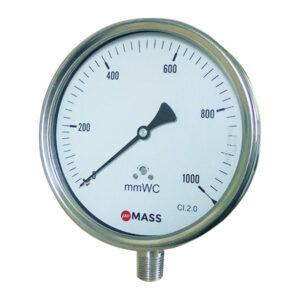

GFB Industrial Pressure Gauges (MASS)

-

Stainless steel process gauges Model ZPS (MASS)

-

Electric Contact Model EC Series (MASS)

-

Diaphragm type pressure gauge Model SDS (MASS)

-

Capsule type pressure gauge Model CPS (MASS)

-

Brass Capsule type pressure gauge Model CPB (MASS)

-

Test Pressure Gauge Model TGS (MASS)

-

WPP Solid Front Process Pressure Gauge (MASS)

-

Bellow type Differential Pressure Gauge Model D100 (MASS)

-

Single Diaphragm Differential Pressure Gauge Model D101 (MASS)