Flow Instrument

Flow Instruments

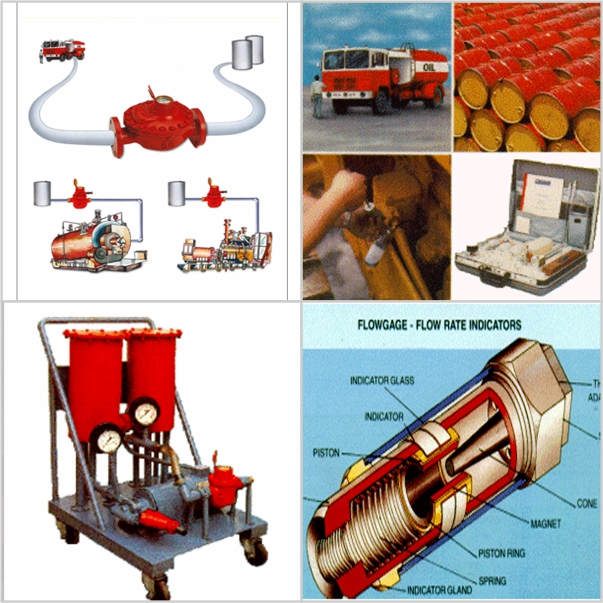

Flow instruments are important tools used in many industries, including water treatment and oil and gas. They measure how fast liquids and gases move through pipes and systems. By providing accurate flow measurements, these instruments help ensure that processes run smoothly and safely. This monitoring not only boosts productivity but also helps reduce waste, making operations more efficient.

Types of Flow Instruments

- Electromagnetic Flowmeters: These devices measure the flow of conductive liquids using magnetic fields. They are highly accurate and ideal for applications like wastewater treatment. As the float moves, it activates a switch or sends a signal, making it ideal for tanks and reservoirs.

- Ultrasonic Flowmeters: These instruments use sound waves to measure flow rates. They are non-invasive and suitable for both liquids and gases, making them versatile for various industries.

- Turbine Flowmeters: These flowmeters measure flow by using a spinning rotor. The speed of the rotor correlates with the flow rate, making them effective for applications requiring high precision.

Flow instruments are available in several types, each suited for different applications:

It is important to understand the unique advantages of each type is crucial for selecting the right flow instrument for your specific needs, whether you require high accuracy or need to operate in harsh conditions.

Enhancing Safety and Compliance with Flow Instruments

In industries that handle hazardous materials, flow instruments are essential for providing safety and meeting regulatory requirements. They monitor flow rates in real-time, helping to prevent overflows, leaks, and other dangerous situations that could pose risks to both people and the environment.

For example, in chemical processing, precise flow measurement can prevent reactions from becoming uncontrolled, while in oil and gas, it can help avoid spills.

Regular calibration and maintenance are crucial for maintaining the accuracy of these instruments, ensuring they provide reliable readings. This vigilance not only protects workers but also helps companies comply with environmental regulations, avoiding costly fines and potential legal issues.

Many flow instruments are equipped with alarms and automated controls that can trigger safety protocols in case of abnormal flow conditions, further enhancing safety and operational integrity.

Future of Flow Measurement

The flow measurement industry is rapidly evolving due to advancements in technology. Smart flow instruments equipped with IoT capabilities are becoming increasingly popular, allowing for remote monitoring and real-time data analysis. These devices enable predictive maintenance, which helps identify potential issues before they lead to failures, thereby minimising downtime and reducing operational costs.

The integration of artificial intelligence (AI) and machine learning is enhancing data interpretation, allowing for better forecasting and process optimisation. Advanced analytics can identify patterns and trends in flow data, helping businesses make informed decisions that improve efficiency.

There is a growing emphasis on sustainability and energy efficiency. New flow measurement technologies are designed to optimise resource usage, reduce waste, and lower energy consumption.

For example, advanced flow meters can help manage water usage in agricultural applications, contributing to more sustainable practices.

As these innovations continue to emerge, we can expect increased automation, improved accuracy, and enhanced safety in flow measurement, leading to smarter, more efficient operations across various industries.

Common Issues with Flow Instruments

- Inaccurate Readings: Factors such as calibration drift, environmental changes, or incorrect installation can lead to misleading flow measurements. Regular calibration and maintenance are essential to ensure accuracy.

- Flow Obstruction: Particles, debris, or sediment can obstruct the flow path, affecting the measurement. Regular cleaning and proper filtration systems can help prevent this issue.

- Sensor Malfunctions: Sensors can fail due to wear and tear, exposure to harsh conditions, or electrical issues. Routine inspections and timely replacements are crucial for maintaining reliability.

It is important to understand how troubleshooting these common issues can minimise downtime and ensure optimal flow measurement accuracy, ultimately enhancing operational efficiency and safety.

Flow instruments, like any equipment, can experience various issues that impact their performance. Common problems include:

Frequently Asked Questions (FAQs)

- What is a Flow Instrument?

A flow instrument is a device used to measure the flow rate of liquids or gases in various applications, ensuring efficient and safe processes. - How Do I Choose the Right Flow Instrument for My Application?

Consider factors such as the type of fluid (liquid or gas), flow range, accuracy requirements, and the environment in which the instrument will operate. - What Maintenance Do Flow Instruments Require?

Regular calibration, cleaning, and inspection are essential to ensure accurate readings and extend the lifespan of the instrument. - Can Flow Instruments Be Used in Hazardous Environments?

Yes, many flow instruments are designed specifically for hazardous environments and come with features like explosion-proof housing and corrosion resistance. - What Are the Latest Trends in Flow Measurement Technology? Current trends include the integration of IoT for real-time monitoring, advanced data analytics, and the use of non-invasive measurement techniques.