ETP Instrumentation & Online Monitoring Solutions

Compliance-ready measurement for Effluent Treatment Plants—flow, level, and analytics with installation discipline and calibration readiness.

Suggested email subject: ETP | Flow / Level / Analytics

Why Instrumentation is Critical in an ETP

ETPs are compliance-driven systems. Stable flow measurement, reliable level control, and accurate online analytics help maintain treatment performance and support regulatory reporting.

In real plants, the biggest failures happen due to installation, access, and maintenance planning—not because the instrument is “low quality”. This page is written to help you avoid those failures.

Key Measurement Parameters (By Process Stage)

Inlet & Equalization

- Flow measurement (inlet / transfer / recycle)

- Tank level measurement (equalization tank, sump)

Treatment Stages

- pH measurement (neutralization dosing control)

- Pressure monitoring (filter/skid duty, where applicable)

Outlet / Discharge

- pH and key analytics as required

- Data logging and alarms for compliance

Selection Logic (Practical Engineering)

Electromagnetic flow meters:

Preferred for conductive liquids common in ETPs. Performance depends heavily on grounding/earthing, maintaining full-pipe conditions, and avoiding upstream disturbances.

Level measurement:

Ultrasonic works well in many clean applications. Radar becomes safer where foam, vapour, turbulence, temperature variation, or condensate can cause false echoes.

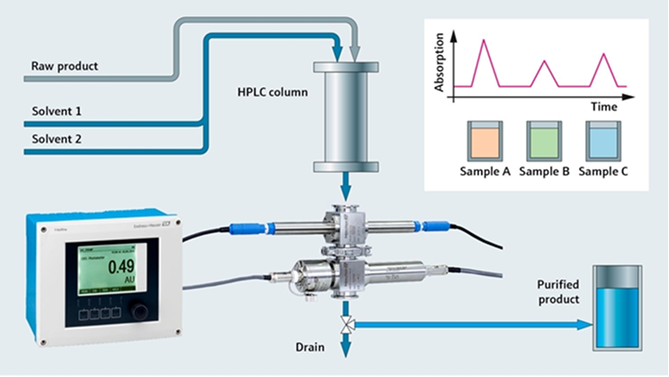

Online analytics:

Sensor location, sample conditioning (if required), and access for calibration are as important as instrument brand.

Tip: If you share where the instrument will be installed (photos or a P&ID), we can recommend a configuration that is stable and service-ready.

Recommended Instrument Stack (Aligned to ETP Reality)

Flow

- Eureka electromagnetic flow meters for water and effluent lines

Level

- NIVELCO level switches and transmitters (technology selected by tank conditions)

pH & Online Analytics

- Endress+Hauser pH and online analytical instruments (as required by compliance and process)

Use the checklist to reduce unstable readings and commissioning delays.

Installation & Commissioning Pitfalls (Most Common)

- Poor grounding/earthing in electromagnetic flow meters → unstable readings

- Partially filled pipes or air entrainment → erratic measurement

- Wrong pH sensor location (dead zones, poor mixing) → incorrect control

- No maintenance access for probes → skipping calibration and slow drift

- No calibration routine planned → compliance risk during audits

System Integration Support (How MTC Helps)

- Share your process conditions, P&ID or application challenge — we’ll help you arrive at a reliable configuration.

- Instrument selection matched to real tank/line conditions

- Advice on installation discipline and serviceability

- Supply and after-sales support for spares and consumables planning

Spec Checklist (Send With Your Email)

- Line size, medium, expected flow range, conductivity (if known)

- ETP stage: inlet / treatment / discharge

- Tank conditions: foam/vapour/turbulence, height, nozzle size

- Analytics requirement: pH only or additional parameters

- Any reporting or logging requirement (if specified by PCB/consultant)

Why MTC