In many industrial plants, flow-related problems don’t announce themselves loudly. A pump runs dry, a chiller trips without warning, or a process line underperforms without a clear reason. Most of the time, the root cause comes down to one simple issue: flow was not monitored, measured, or indicated correctly.

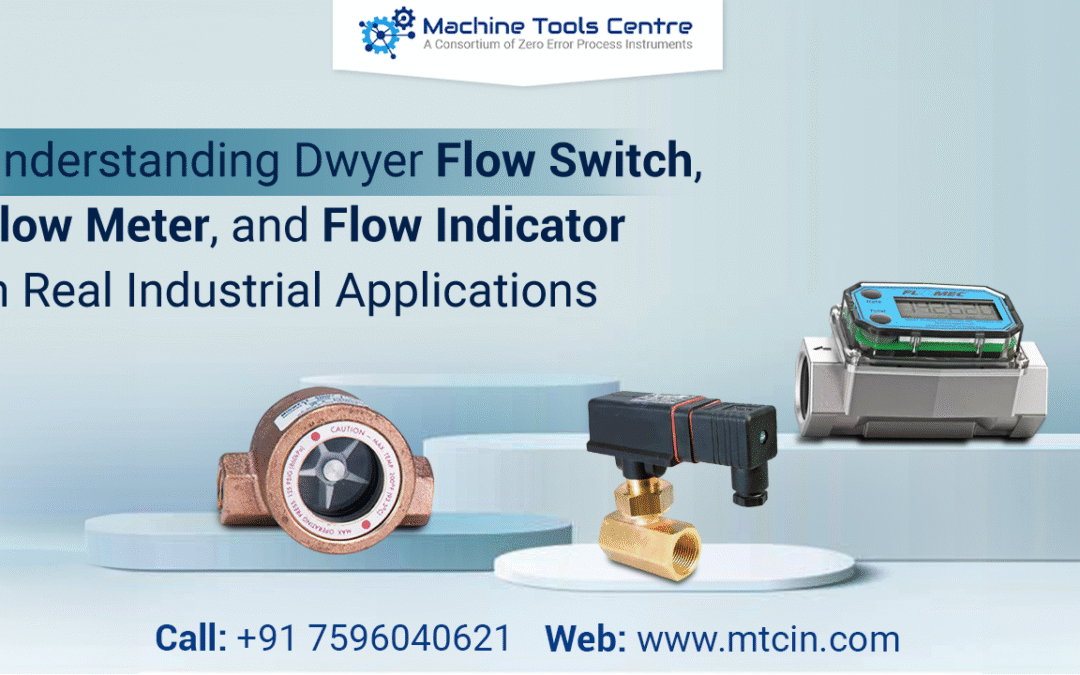

This is where reliable instruments like the Dwyer flow switch, Dwyer flow meter, and Dwyer flow indicator play a critical role. These devices may look simple, but in real-world operations, they are often the first line of protection against equipment damage, downtime, and safety risks.

This article explains how these three instruments differ, where each one fits best, and how engineers and maintenance teams actually use them on the field.

Why Flow Control Matters More Than Most People Think

Flow is not just about quantity. It directly affects:

- Heat transfer efficiency

- Pump and motor protection

- Product quality

- Energy consumption

- System safety

In HVAC systems, insufficient water flow can damage chillers. In compressed air systems, incorrect flow affects tool performance. In process industries, uncontrolled flow can lead to inconsistent output or even hazardous conditions.

That’s why experienced engineers don’t rely on assumptions. They rely on proper flow devices—selected correctly and installed properly.

What Is a Dwyer Flow Switch and Where It Is Used

A Dwyer flow switch is used when the requirement is simple but critical:

Is there flow or not?

It does not measure how much fluid is flowing. Instead, it detects whether flow is present above or below a set point and then triggers an electrical signal.

How a Dwyer Flow Switch Works in Practice

In most installations:

- The flow switch is mounted directly on the pipe

- When flow reaches a preset level, the internal mechanism activates

- This sends a signal to a control panel, PLC, or alarm system

That signal may:

- Start or stop a pump

- Shut down a system to prevent damage

- Trigger an alarm for operators

Common Applications

- Chiller and boiler protection

- Pump dry-run prevention

- Cooling water confirmation

- Fire protection systems

- Compressor cooling lines

In these cases, the exact flow rate is not important. What matters is confirmation of flow.

Why Engineers Prefer Dwyer Flow Switches

- Reliable mechanical design

- Simple operation

- Long service life

- Suitable for harsh environments

A properly selected Dwyer flow switch often runs for years with minimal attention.

Understanding Dwyer Flow Meters in Industrial Systems

Unlike a flow switch, a Dwyer flow meter is used when accurate flow measurement is required.

It answers questions like:

- How much air is flowing through this duct?

- What is the water flow rate in this line?

- Is the process operating within the specified range?

Real Difference Between Monitoring and Measuring

This distinction is important:

- Flow switch → confirms presence or absence

- Flow meter → provides numerical flow data

In process control, flow data often affects:

- Chemical dosing

- Heat exchange efficiency

- Energy optimization

- Quality control

Types of Dwyer Flow Meters Commonly Used

Depending on the application, Dwyer offers:

- Air and gas flow meters

- Liquid flow meters

- Inline and panel-mounted designs

Each type is selected based on:

- Media type

- Pressure and temperature

- Required accuracy

- Installation constraints

Installation Realities Engineers Face

In real plants:

- Straight pipe length is often limited

- Space may be tight

- Access for maintenance is important

Dwyer flow meters are popular because they are

- Compact

- Easy to read

- Simple to maintain

When installed correctly, they provide consistent and dependable readings without constant recalibration.

Role of Dwyer Flow Indicator on the Plant Floor

A Dwyer flow indicator is sometimes underestimated, especially in an age of digital displays. However, on actual shop floors and mechanical rooms, visual confirmation still matters.

What a Flow Indicator Does

- Shows flow movement visually

- Requires no power supply

- Allows instant confirmation during inspection

For maintenance teams, this is extremely valuable.

Typical Applications

- Cooling water lines

- Lubrication systems

- Utility pipelines

- Maintenance verification points

In many cases, technicians just need to know one thing: “Is fluid moving through this line right now?” A Dwyer flow indicator answers that immediately.

Side-by-Side Comparison for Practical Selection

| Device | Primary Function | Typical Use | Key Advantage |

| Dwyer Flow Switch | Detects flow presence | Pump & equipment protection | Simple, dependable |

| Dwyer Flow Meter | Measures flow rate | Process control & optimization | Accurate readings |

| Dwyer Flow Indicator | Visual confirmation | Maintenance & inspection | No power required |

This table reflects how these devices are actually used—not how they are described in catalogs.

How to Select the Right Dwyer Flow Device

Choosing the wrong flow instrument is a common mistake, often caused by overengineering or underestimating requirements.

Key Questions to Ask Before Selection

- Do I need a measurement or just confirmation?

- What is the media (air, water, gas, or liquid)?

- Operating pressure and temperature?

- Pipe size and material?

- Electrical output required or not?

Common Selection Mistakes

- Using a flow meter where a flow switch would suffice

- Ignoring pressure drop considerations

- Choosing based on price instead of application

- Incorrect installation orientation

Experienced suppliers like Machine Tool Centre help avoid these mistakes by matching the application with the right Dwyer instrument.

Installation and Maintenance Insights from the Field

Even the best instrument fails if installed incorrectly.

Practical Installation Tips

- Ensure correct flow direction

- Maintain recommended straight pipe lengths

- Avoid mounting near turbulence sources

- Verify electrical connections properly

Maintenance Reality

- Flow switches: minimal maintenance

- Flow meters: periodic inspection

- Flow indicators: visual cleaning when needed

Dwyer instruments are known for requiring low maintenance, which is why they are commonly used in continuous operation systems.

Why Using Original Dwyer Instruments Matters

In industrial systems, accuracy and reliability are not optional. Using non-genuine or unverified products can lead to:

- Incorrect readings

- Delayed response

- Equipment damage

- Safety risks

Sourcing original Dwyer products through trusted suppliers like Machine Tool Centre ensures:

- Correct specifications

- Long-term reliability

- Manufacturer-backed performance

This is especially important in regulated or safety-critical environments.

Practical Use Cases from Industry

HVAC Chiller Protection

A Dwyer flow switch ensures water circulation before allowing chiller startup, preventing heat exchanger damage.

Compressed Air System Monitoring

A Dwyer flow meter helps identify leaks and optimize air consumption.

Cooling Water Verification

A Dwyer flow indicator provides instant visual confirmation during maintenance rounds. These are everyday applications where flow devices quietly prevent expensive failures.

Conclusion

Flow instruments may not be the most visible part of an industrial system, but they are among the most important. Whether it’s a Dwyer flow switch protecting equipment, a Dwyer flow meter ensuring process accuracy, or a Dwyer flow indicator assisting maintenance teams, each device serves a specific and valuable purpose.

The key lies in:

- Understanding the requirement

- Selecting the right device

- Installing it correctly

- Sourcing it from a reliable supplier

With proper selection and original instruments supplied through the Machine Tool Centre, these devices continue to deliver dependable performance in demanding industrial environments.